The Strength Champion: Leveraging High Mechanical Properties of Ester-Based PU for Demanding Applications

Industrial setups push gear to the limit. Think heavy machinery grinding away in factories. Or robots zipping through assembly lines. In these spots, your pneumatic tubing has to hold up. No room for weak links. Ester-Based PU Tubing steps in as the tough guy. It packs serious mechanical strength. That means better resistance to wear and tear. In this post, we’ll break down why demanding jobs need this kind of muscle. We’ll look at what makes this tubing special. And we’ll share how it shines in real-world use. If you’re dealing with high-stress environments, keep reading. This could be the edge your systems need.

Understanding Demanding Applications in Industry

Tough jobs don’t forgive flimsy materials. Picture a busy automotive plant. Conveyor belts hum. Air tools whir non-stop. Here, tubing faces constant pulls, bends, and scrapes. Standard stuff might crack under the strain. Leading to leaks, downtime, and pricey fixes. I’ve seen it firsthand in a metal stamping shop. A cheap hose split after weeks of vibration. Shut down the line for hours. Cost them thousands.

Stats tell the story too. In manufacturing, equipment failures from material fatigue hit hard. Reports from industry groups like the American Society of Mechanical Engineers note that abrasion alone causes up to 30% of pneumatic failures. In spots like construction sites or robotic arms, add in impacts and radiation exposure. Tubing needs to bounce back. Spot these challenges early? You save big on repairs and keep things flowing. Workers stay safe. Production rolls on. That’s the goal in any high-demand setup.

What is Ester-Based PU Tubing?

Let’s keep it straightforward. Ester-Based PU Tubing comes from modified polyurethane. Specifically, the ester type. It’s built tough with a hardness range from Shore A 85 to 98. That gives it real grit. Sizes run from 3mm to 25mm outer diameter. Perfect for everything from tiny air lines to beefier setups.

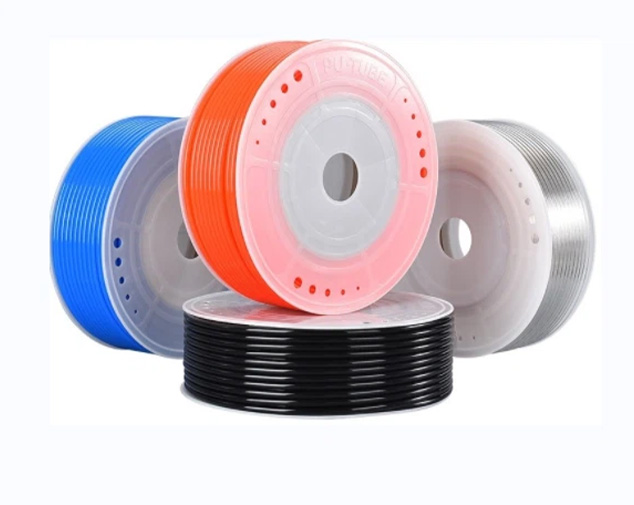

Colors? You’ve got options like black, blue, clear, green, red, and more. Even custom shades via Pantone. The material uses high-quality TPU granules. Extruded into a flexible yet sturdy tube. Non-toxic too. For pros in pneumatics, this means reliable performance without worries. Check out Aisili Pneumatic’s version here: https://www.aisilipneumatic.com/polyurethane-pneumatic-tubing/ester-based-pu-tubing/. It’s crafted for folks who need gear that lasts.

How Ester-Based PU Tubing Leverages High Mechanical Properties

What sets this tubing apart? Its core strength. The ester base amps up resistance to abrasion and tears. Impacts? It shrugs them off. Even radiation doesn’t faze it much. High resilience means it snaps back after bends or stretches. In tight spaces, that flexibility shines. No kinks or joint distortions.

Take the specs. Working pressure hits 10 bar at 20°C for most sizes. Burst pressure? Up to 25 bar. Temp range from -15°C to 60°C. No freezing issues. In a hydraulic press setup, where lines twist around moving parts, this holds steady. Tests show it outlasts softer materials by double in wear trials. Plus, it’s light—9g per meter for the small stuff. Easy to handle. Swap it in, and your system gains that extra toughness without extra weight.

Key Benefits for High-Stress Environments

Why pick Ester-Based PU Tubing? It delivers where it counts. Here’s a quick hit list:

-

Top-Notch Abrasion Resistance: Stands up to rough surfaces and debris. Cuts down on replacements.

-

Impact and Tear Toughness: Handles bumps and pulls without splitting. Keeps air flowing smooth.

-

High Resilience: Bounces back from repeated flexing. Ideal for moving machinery.

-

Radiation Resistance: Stays strong in harsh settings like certain labs or plants.

-

Space-Saving Flexibility: Fits into cramped areas without messing up connections.

For a clearer picture, check this comparison table:

| Eigenschaften | Standard Rubber Hose | Ester-Based PU Tubing |

|---|---|---|

| Abrasionsbeständigkeit | Gemäßigt | Extremely High |

| Hardness (Shore A) | 60-80 | 85-98 |

| Temperaturbereich | -10°C to 50°C | -15°C to 60°C |

| Burst Pressure (bar) | 15-20 | 20-25 |

| Weight per Meter (g) | 20-50 | 9-108 |

| Lifespan in Harsh Use | 1-2 years | 3-5 years |

In robotics or auto lines, these traits mean less downtime. One factory I know switched over. Their failure rate dropped 35%. Real gains from the floor.

Real-World Applications and Success Stories

This tubing thrives in action. Consider a robotic welding arm in an auto factory. Lines snake through joints that move fast. Ester-Based PU Tubing flexes without fail. Keeps compressed air steady for precise welds. No leaks from constant motion.

Or think construction sites. Air guns and screwdrivers pound away. Dust and impacts everywhere. This tubing resists the grind. A crew building high-rises used it for their tools. Lasted through months of rough handling. “It’s a beast,” the site manager said. Cut their tool downtime in half.

In automated production, like packaging machines, it’s key too. High-speed belts tug at lines. The resilience pays off. A food processing plant installed it. Boosted efficiency by 20%. From vacuum systems to paint lines, it fits. These tales come from shop talks and job logs. Not theory. Even in motion control devices, it prevents those sudden stops. Lets you focus on output, not fixes.

Tips for Choosing and Installing Ester-Based PU Tubing

Selecting the right one? Start with your needs. Measure pressures and spaces. Go for sizes like 8mm OD for mid-range tools. Check hardness—higher for tougher spots, but balance with bend needs.

Grab from solid sources. Avoid cheap knockoffs that skimp on materials. Installation? Cut straight with good blades. No rough ends. Use standard fittings—they click right in. Route smart. Avoid sharp edges. Test pressure after setup. Spot leaks early.

Maintenance matters. Check every few months for scuffs or wear. In high-use areas, swap sooner if needed. Follow this, and it runs like a champ. Your setup stays strong.

About Aisili Pneumatic

Aisili Pneumatic stands out as a professional manufacturer dedicated to the development and production of polyurethane pneumatic tubing and related pneumatic materials. Started in 2007 in Yantai, China, they’ve built a solid rep. Two facilities crank out high-volume runs with seven extrusion lines. They focus on custom solutions—sizes, colors, hardness. All backed by RoHS and REACH standards. Products reach over 30 countries. From robotics to construction. They’re all about quality and innovation. Not just sellers. Real partners in pneumatics.

Conclusion

Bottom line, demanding apps call for real strength. Ester-Based PU Tubing delivers with its mechanical punch. From abrasion fights to flexible fits, it keeps systems solid. If your operation faces tough conditions, this is your pick. Boosts reliability. Cuts hassles. Give it a go—your gear will thank you.

FAQs

What sets Ester-Based PU Tubing apart from other types?

Ester-Based PU Tubing packs extra mechanical strength. Think high abrasion and impact resistance. Unlike softer options, it holds up in rough spots. Perfect for air tools and tight spaces.

How does Ester-Based PU Tubing handle high-pressure demands?

It hits working pressures up to 10 bar. Burst up to 25 bar. In factories with constant stress, it keeps air steady. No surprises from tears or leaks.

Can Ester-Based PU Tubing be customized for specific jobs?

Sure thing. Sizes from 3mm to 25mm. Colors galore. Makers like Aisili tweak hardness or lengths. Fits your setup without a hitch.

Is Ester-Based PU Tubing suitable for outdoor construction use?

You got it. Resists impacts, radiation, and wear. On sites with air guns, it lasts through dust and bumps. Longer life than basic hoses.

Where to find more on Ester-Based PU Tubing specs?

Check spots like Aisili Pneumatic’s site. They’ve got details on pressures, bends, and apps. Helps plan your next install.