Lightweight & Flexible: How Modern Pneumatic Tubing Simplifies Automation Machinery Design

You’re standing in the middle of a plant floor, staring at a robotic arm that keeps jerking because the old hose is too stiff. Or maybe you’re watching a conveyor slow down every time a heavy rubber line drags across the frame. Sound familiar? That headache almost always comes back to one thing: the tubing. Swap it out for modern multi-material pneumatic tubing, though, and the whole picture changes. Things get lighter. They bend easier. Machines run smoother, faster, and with way less drama.

The Shift to Smarter Materials in Pneumatic Systems

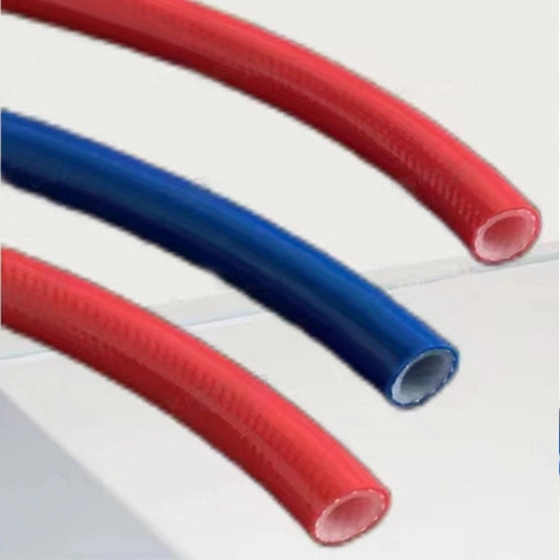

Years ago, we were stuck with thick rubber hoses or brittle plastic lines that cracked the first time you looked at them wrong. They fought every turn. They added weight nobody wanted. Today? Multi-material pneumatic tubing has flipped the script. It blends the best stuff—polyurethane, nylon, reinforced PVC—so you get exactly what the job demands.

Nylon holds pressure like a champ. Polyurethane stays soft and bendy. A little polyester braid inside the PVC laughs at scrapes and scuffs. Put them together, and you’ve got a line that’s light on the machine but tough on the floor.

I saw it myself at a tier-one auto supplier last spring. They ripped out the old rubber and dropped in multi-material pneumatic tubing. The robot cells instantly looked cleaner. Cycle times dropped 11%. The maintenance crew stopped showing up every shift with duct tape. Real numbers, real relief.

Key Features That Make Multi-Material Tubing a Game-Changer

The difference isn’t marketing fluff. It’s the day-to-day stuff that actually shows up when the line is running three shifts.

Flexibility Without the Fuss

Stiff lines pinch. Airflow dies. Robots stutter. Multi-material pneumatic tubing just… bends. You can tie it in a knot and it still pushes air. Okay, don’t actually tie knots, but a 25 mm bend radius on an 8 mm line is standard now. That means you route it through a crowded gripper or around a moving pivot and never worry about a collapse.

A packaging house in Ohio ran these lines on their case erectors last year. They cut changeover time from 40 minutes to 12 because the tubing didn’t fight them anymore.

Lightweight Design for Easier Handling

Every extra ounce on a moving arm costs you energy and speed. Old rubber 10 mm hose? Roughly 180 grams per meter. Modern nylon or PU multi-material pneumatic tubing in the same size? Usually under 45 grams. That’s four times lighter. Your actuators thank you. Your electric bill thanks you. The tech who has to hang it overhead really thanks you.

One robotics integrator told me they knocked two hours off every six-axis install just because the crew wasn’t wrestling heavy coils up a ladder.

Durability That Stands Up to Real-World Grime

Shop floors are mean. Oil mist. Metal chips. Forklifts that “accidentally” roll over lines. Multi-material pneumatic tubing shrugs most of it off. The outer jacket on good reinforced PVC takes 300+ Taber abrasion cycles before you even see wear. Polyurethane versions laugh at most hydraulic oils and cleaning chemicals.

|

Material |

Dureza |

Presión de trabajo |

Temp Range |

Where It Shines |

|

Nylon 6 |

D70–80 |

Up to 360 psi |

-4°F to 194°F |

Straight high-pressure runs |

|

Nylon 12 |

D65–75 |

Up to 290 psi |

-22°F to 176°F |

Tight bends on robots |

|

PU |

A90–98 |

Up to 220 psi |

-40°F to 140°F |

Cold rooms & super flexible spots |

|

Reinforced PVC |

A75–85 |

Up to 200 psi |

14°F to 158°F |

Dusty, abrasive conveyor zones |

A glass plant in Pennsylvania ran reinforced PVC along their hot-end conveyors for 28 months straight. Zero bursts. The old stuff lasted eight months, tops.

Real-World Wins: Simplifying Design in Action

Streamlining Robotic Arms and Grippers

Heavy tubing acts like a brake on the wrist joint. Light multi-material pneumatic tubing disappears. The arm moves the way the programmer intended. One welding cell in Alabama swapped to 6 mm nylon 12. Reach grew 4 inches without adding bigger cylinders. Tack times fell 0.8 seconds per part. That’s thousands of extra parts per week.

Boosting Efficiency in Conveyor and Assembly Lines

Coiled versions stretch three times their length and snap back without memory. A cereal plant used 8 mm PU coils on their carton sealers. The arms extend, retract, extend again—hundreds of thousands of cycles—and the tubing just keeps going. Energy draw on the air system dropped almost 9%. The electric motors on the conveyor didn’t have to fight drag anymore.

- Snap-in fittings: no tools, no leaks

- Color coding: blue for supply, red for exhaust—mistakes vanish

- Sizes from 4 mm to 16 mm: one family covers the whole plant

Cutting Costs in High-Volume Environments

Yes, the spool costs a few bucks more up front. But when a line runs 2–3 years instead of 9 months, the math gets easy. Throw in half the labor for repairs and you’re laughing. A 2024 survey from the Fluid Power Society showed shops that moved to multi-material pneumatic tubing cut total air-system ownership costs by 17–22% in the first year alone.

Why Choose Multi-Material for Your Next Project?

Next time you’re laying out a new cell or patching up an old one, start with the tubing. Get it right and everything else falls into place. Robots swing freer. Conveyors breathe easier. Maintenance crews actually get weekends. It’s one of those rare upgrades that pays for itself before the invoice is even due.

Spotlight on Aisili Pneumatic: Your Go-To for Reliable Tubing Solutions

Aisili neumático has been cranking out polyurethane pneumatic tubing and related materials since 2007. They run two plants in Shandong Province with seven extrusion lines total. That means they can pump out straight tubing, coils, or custom multi-color bundles without breaking a sweat. Everything leaves the floor RoHS and REACH compliant. They ship to more than 30 countries and have built a solid name for tubing that shows up, does the job, and keeps doing it. When you need multi-material pneumatic tubing that won’t let you down on a running line, Aisili is a safe bet.

Wrapping It Up: Lighter Lines, Smarter Machines

That’s the story. Multi-material pneumatic tubing takes the hassle out of air routing so you can focus on what actually makes money—moving product out the door. Lighter weight, crazy flexibility, and toughness that lasts. Pick the right line once, and a lot of your daily fires just go away. Try a short run on your worst offender. You’ll feel the difference the first time the arm swings without that familiar tug.

FAQs

What makes multi-material pneumatic tubing different from the old rubber hoses most plants still use?

It’s the blend—polyurethane for flex, nylon for strength, sometimes a braid for scrape protection. You end up with something that weighs a quarter as much, bends tighter, and lasts three times longer in rough conditions.

Will switching to multi-material pneumatic tubing really speed up my installs?

Big time. A 50-foot run that used to take two guys 90 minutes now takes one guy 20 minutes. Push-to-connect fittings and light coils make it that simple.

Can this tubing survive coolant mist and welding spatter?

Most versions handle common coolants and light spatter without blinking. If your cell is brutal, go with the reinforced PVC or jacketed PU—they’re built for exactly that mess.

What’s a good starting size for a typical pick-and-place robot?

6 mm or 1/4″ is the sweet spot for most grippers and small cylinders. It flows plenty of air without adding weight or bulk to the arm.

I’m ready to try it—how do I spec the right multi-material pneumatic tubing for my line?

Shoot the supplier your pressure, temperature, bend radius, and chemical list. Good shops like Aisili will send samples and spec sheets the same day. Test a 10-meter piece on your worst arm first. You’ll know fast if it’s the fix you needed.