Common Pneumatic Tubing Problems and Best Practices to Prevent System Failure

Pneumatic systems keep factories running smoothly. They power everything from robotic arms to assembly lines. At the heart of these setups sits the tubing. PU pneumatic tubing, in particular, gets a lot of use because it bends easily and holds up well. But things go wrong sometimes. Leaks pop up. Tubes wear out fast. Or worse, a line bursts without warning.

Picture this: A busy automotive plant. Cylinders fire hundreds of times an hour. Suddenly, one stops. Downtime hits. The culprit? A cracked tube letting air escape. That costs thousands in lost production. Or think about a packaging facility in a humid area. Moisture sneaks in and eats away at the tubing over months. Failures like these happen more than you’d think.

This article looks at the most common issues with pneumatic tubing. We’ll cover real causes based on what happens in shops every day. Then, we’ll share straightforward ways to stop them. Good habits here can cut breakdowns and keep your lines humming.

Why Pneumatic Tubing Matters in Industrial Systems

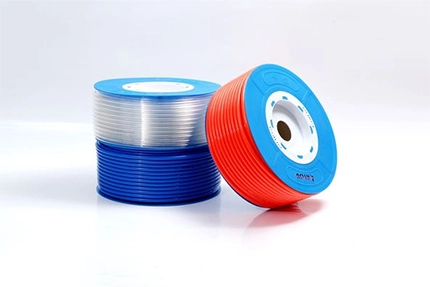

Compressed air flows through tubes to valves, cylinders, and tools. PU pneumatic tubing stands out for its mix of toughness and flexibility. It resists kinks in tight spots. It bounces back after bending. And it handles everyday wear in automation, robotics, and manufacturing.

But tubing takes a beating. It deals with constant pressure changes. Vibration shakes it. Abrasion rubs against edges. Add in moisture or chemicals, and problems build up. Industry folks know that up to 30% of pneumatic issues trace back to bad tubing or poor setup. Fixing that early saves headaches.

Common Pneumatic Tubing Problems

Issues show up in different ways. Some hit fast. Others creep in slowly. Here’s a breakdown of the big ones engineers run into.

|

Problem |

Common Causes |

Real-World Impact |

|

Air Leaks |

Loose fittings, cracks, worn seals |

Drops pressure, slows actuators, wastes energy |

|

Abrasion and Wear |

Rubbing on machinery, dragging on floors |

Thins walls, leads to bursts or sudden failures |

|

Kinking or Collapsing |

Sharp bends, too-tight turns |

Blocks flow, causes erratic cylinder movement |

|

Moisture Damage |

Condensate in lines, humid environments |

Degrades material, shortens tube life by months |

|

Overpressure Bursts |

Exceeding rated pressure, spikes from compressors |

Dangerous explosions, downtime for repairs |

|

Chemical Degradation |

Exposure to oils, cleaners, or lubricants |

Softens or brittles tubing, leads to cracks |

|

Aging and Cracking |

UV exposure, heat, long-term use |

Brittle tubes fail unexpectedly in older systems |

These aren’t rare. In food plants, moisture often wins. Tubes degrade quietly until they split. In dry shops with lots of movement, abrasion takes over.

Air Leaks: The Silent Energy Thief

Leaks waste air. A small one might not seem bad. But add them up—they can eat 20-40% of compressor output. Listen for hissing around fittings. Or use soapy water to spot bubbles. Loose connections or cut tubes cause most. In one warehouse setup, poor cuts led to leaks that slowed picking robots all shift.

Abrasion: Wear from Daily Grind

Tubes drag over edges or vibrate against frames. The outer layer thins. Then, boom—a hole. Outdoor equipment sees this a lot from dirt and movement. Factories with conveyors report tubes wearing out in under a year if not protected.

Kinking and Restricted Flow

Bend too sharp, and the tube folds in on itself. Air struggles through. Cylinders move slow or jerky. Mobile tools like air guns suffer when coiled hoses kink during use.

Moisture and Hydrolysis Issues

Compressed air carries water if not dried right. In PU pneumatic tubing, that leads to breakdown over time. Humid summers speed it up. Plants in warm climates see tubes cracking sooner without good dryers.

Bursts from Overpressure

Push beyond limits, and tubes explode. Bad regulators or blocked vents cause spikes. Safety risks jump here—flying pieces can hurt people nearby.

Real-World Examples of Tubing Failures

Take a robotics line in an auto factory. Tubes routed near moving arms wore from constant rubbing. Abrasion led to leaks. Production halted for hours. Switching routes and adding sleeves fixed it.

Or a packaging plant. High humidity plus poor air drying. Tubes degraded fast. Replacements every few months. Installing better dryers and checking condensate traps cut failures big time.

Data backs this. Shops with regular checks see 40% fewer tube-related stops. Simple stuff makes a difference.

Best Practices for Installation

Get it right from the start. That prevents half the troubles.

- Cut clean and square.Use a sharp tubing cutter. Jagged ends leak at fittings.

- Leave some slack.Tight pulls stress tubes over time. Extra length handles movement without stretching.

- Mind the bend radius.Don’t force sharp turns. Follow maker guidelines—usually 5-10 times the outer diameter.

- Secure properly.Clips or ties keep tubes from rubbing. But don’t crush them.

- Use the right fittings.Push-to-connect for quick jobs. Make sure they match tube size.

- Protect from harm.Sleeves or guards where abrasion hits.

In one install, guys skipped slack on a robot arm. Tubes pulled and kinked during motion. Adding loops solved it smooth.

Maintenance Tips to Extend Tubing Life

Check often. Catch small issues early.

- Inspect visually weekly. Look for wear, cracks, or discoloration.

- Drain condensate daily from filters and traps. Keeps moisture out.

- Test for leaks monthly with soap solution.

- Replace worn sections fast. Don’t patch—swap out.

- Clean around lines. Dirt speeds abrasion.

- Monitor pressure. Stay within ratings.

Plants that drain traps regular report way longer tube life. One shop cut replacements by half just from better drying.

Choosing the Right PU Pneumatic Tubing

Pick based on your setup. High humidity? Go for hydrolysis-resistant types. Heavy wear? Thicker walls or reinforced. Custom colors help trace lines quick in big systems.

Quality matters. Good raw materials mean better resistance to oils, cold, or heat.

About Aisili Pneumatic

Aisili pneumatique is a professional manufacturer dedicated to the development and production of polyurethane pneumatic tubing and related pneumatic materials. Started in 2007 in Yantai, China, the company now runs modern facilities with advanced extrusion lines. They focus on high-performance PU tubing for automation, robotics, and more. With over 17 years in the game, Aisili uses top-grade materials for flexibility and durability. Products meet RoHS and REACH standards. They serve customers in over 30 countries with custom sizes, colors, and fast delivery.

Conclusion

Pneumatic tubing problems like leaks, wear, and bursts don’t have to derail your operation. Spot the common causes—moisture, bad installs, abrasion—and tackle them head-on. Clean cuts, proper routing, regular checks, and good drying go a long way. Pick solid PU pneumatic tubing suited to your environment. Follow these steps, and you’ll see fewer stops, lower costs, and smoother runs. Your system stays reliable day in, day out.

FAQs

What causes the most common leaks in PU pneumatic tubing?

Loose fittings or poor cuts top the list. Cracks from wear come next. Check connections often—soap water spots bubbles quick.

How can I stop abrasion damage on pneumatic tubing?

Route away from rough edges. Add protective sleeves where it rubs. Clips hold it steady without dragging.

Why does moisture ruin PU pneumatic tubing so fast?

Water breaks down the material over time, especially in humid spots. Drain traps daily and use dryers to keep it out.

What’s the best way to avoid kinks in pneumatic tubing?

Leave slack and follow bend rules. No sharp twists. Coils work great for tools that move a lot.

How often should I replace PU pneumatic tubing in a busy factory?

Depends on conditions, but inspect monthly. Swap worn parts right away. Good maintenance can double life in tough setups.