In the world of pneumatic tubing, not all polyurethane is created equal. While polyester-based PU tubing is known for its toughness and resistance to abrasion, ether-based polyurethane tubing brings a different set of strengths to the table—especially when it comes to moisture resistance, long-term flexibility, and stability in humid environments.

For many industries, particularly in automation, medical devices, packaging, and air tools, choosing ether-based polyurethane tubes means better reliability and longer service life in demanding conditions.

What Is Ether-Based Polyurethane?

Ether-based polyurethane (often abbreviated as PU-Ether) is a thermoplastic elastomer created by combining a polyether polyol with diisocyanates. This unique molecular structure provides excellent resistance to hydrolysis, meaning it won’t break down easily when exposed to water or humid environments over time.Compared to polyester-based polyurethane, PU-Ether tubing maintains flexibility better over time, especially in damp conditions, and is far less likely to become brittle or crack.

✅ Ether vs. Polyester: What’s the Difference?

|

Feature |

Ether-Based PU |

Polyester-Based PU |

|

Water Resistance |

Excellent (won’t degrade in humid air or wet environments) |

Poor to moderate (can hydrolyze over time) |

|

Flexibility (Long-Term) |

Superior flexibility retention |

May harden or become brittle over time |

|

Abrasion Resistance |

Good |

Excellent |

|

Chemical Resistance |

Moderate |

Better with oils, fuels, and solvents |

|

Temperature Tolerance |

Typically -40°C to +70°C |

Typically -20°C to +60°C |

|

Ideal Use Environment |

Indoor systems, humid areas, food contact |

Harsh outdoor, oily or mechanical friction conditions |

Why Choose Ether-Based Polyurethane Tubing?

There are several scenarios where PU-Ether tubing offers significant advantages:

✅ 1. Superior Hydrolysis Resistance

Ether PU tubing remains stable in wet, high-humidity, or water-prone environments, making it ideal for food processing, beverage systems, laboratories, and general indoor air lines.

✅ 2. Soft and Flexible for Easy Handling

Its soft texture and low compression set make it easier to route in compact systems or mobile machinery. Even after extended use, the tubing retains its flexibility and doesn’t develop surface cracks.

✅ 3. Low Odor and FDA-Grade Options

For applications where hygiene and safety matter—such as medical gas delivery or compressed air lines in clean areas—ether PU is available in non-toxic, low-odor, and food-grade compliant versions.

✅ 4. UV and Oxidation Resistance

PU-Ether has better stability against UV degradation and ozone, giving it a longer working life in both indoor and light outdoor applications.

Typical Applications of PU-Ether Tubing

Pneumatic control lines in humid factories

Medical device air lines

Compressed air distribution

Packaging and bottling machines

Food & beverage processing equipment

Semiconductor manufacturing lines

Product Features at a Glance

Material: Ether-based thermoplastic polyurethane (TPU-Ether)

Hardness: Typically 95A, customizable

Pressure Range: Up to 10 bar, varies with size

Temperature Range: -40°C to +70°C

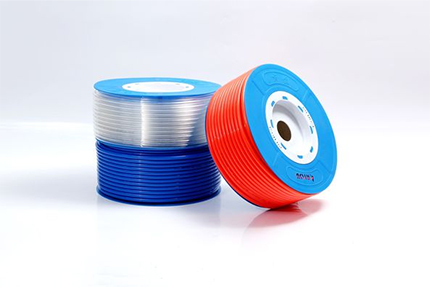

Standard Colors: Clear, blue, black, red, yellow

Customization: Available in multiple inner/outer diameters and lengths

Why Aisili Pneumatic?

At Yantai Aisili New Material Co., Ltd., we manufacture PU-Ether tubing using high-precision extrusion machines, with a strict focus on dimensional accuracy, purity, and consistency. Each batch undergoes rigorous testing for flexibility, pressure resistance, and surface finish.

We provide:

Custom printing and color

OEM/ODM support

Fast lead times

Export-grade packaging and logistics

One-stop pneumatic tubing solutions for industrial clients worldwide

Get a Quote or Sample Now

Whether you’re designing a new pneumatic control system or replacing worn tubing, our PU-Ether pneumatic tubes are built for performance and peace of mind. Reach out to us for a free quote, sample request, or to discuss your custom needs.