Polyester vs. Ether Polyurethane Pneumatic Tubing: How to Choose the Right One?

In the world of industrial automation and pneumatic systems, polyurethane (PU) tubing has become a standard choice for air and fluid transfer. However, when it comes to selecting the right type of polyurethane tubing, many buyers face the same question:

“Should I choose polyester-based or ether-based polyurethane tubing?“

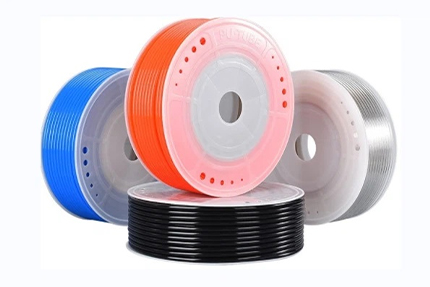

Though they may look similar at first glance, these two types of PU tubes have different chemical structures and physical properties that make them better suited for different environments.

In this article, we’ll break down the differences, pros, cons, and best-use scenarios to help you make a smart, informed decision.

What’s the Core Difference Between Polyester and Ether PU?

Both polyester and ether polyurethane are thermoplastic elastomers. The main difference lies in the polyol component used in their formulation:

Polyester-based PU uses polyester polyols

Ether-based PU uses polyether polyols

This slight chemical change has a big impact on how each material performs under stress, humidity, chemicals, and aging.

Side-by-Side Comparison Table

|

Property |

Polyester PU Tubing |

Ether PU Tubing |

|

Flexibility |

Very flexible when new, stiffens over time |

Stays flexible longer |

|

Abrasion Resistance |

Excellent |

Good |

|

Oil/Fuel Resistance |

Very good |

Moderate |

|

Water Resistance |

Poor (hydrolysis-prone) |

Excellent (hydrolysis-resistant) |

|

UV Stability |

Good |

Better |

|

Temperature Range |

-20°C to +60°C |

-40°C to +70°C |

|

Cost |

Generally lower |

Slightly higher |

|

Recommended Use |

Dry, abrasive, mechanical systems |

vonments |

Why Polyester PU Tubing?

Polyester-based polyurethane tubing is known for its high strength, resistance to wear, and sharp response under pressure. It’s a popular choice for:

Robotics and moving machinery

Pneumatic automation systems

Air tools and workshop equipment

Harsh mechanical environments

✅ Choose Polyester PU Tubing If:

Your system is dry and has frequent movement or abrasion

You require toughness over time

Cost is a key factor and the environment is controlled

Why Ether PU Tubing?

Ether-based polyurethane tubing stands out for its moisture resistance, long-term flexibility, and stability under UV or ozone exposure. It’s often used in:

Medical and food-grade systems

Cleanrooms and labs

Outdoor or humid environments

Sensitive air line systems

✅ Choose Ether PU Tubing If:

Your application involves humidity, moisture, or steam

You need FDA-grade, low-odor tubing

Your system needs tubing that stays flexible over time

Expert Tip from Aisili Pneumatic

If you’re not sure which one to use, start by asking these 3 questions:

Will the tubing be exposed to water or humidity?

→ If yes, go with ether-based PU.

Is the system under mechanical stress or friction?

→ If yes, polyester-based PU may be better.

Is long-term flexibility and aging resistance critical?

→ Choose ether-based PU for longer stability

🌐Still Not Sure What You Need?

At Aisili Pneumatic, we specialize in custom polyurethane tubing solutions tailored to your application. Whether you’re building a high-speed packaging line or a precision lab system, we’ll help you choose the most cost-effective and high-performance tubing for your needs.

You can also contact us directly for:

Technical data sheets

Custom color and size requests

OEM branding and bulk orders

Free samples for evaluation